The exhibition is one of the most significant industry events for chemical manufacturers, engineering companies, suppliers of the laboratory and industrial equipment, as well as educational organizations involved in training personnel for the chemical industry.

“A large team of scientists from TSU and ICTC involved 12 people. Among the most significant results, we can mention agreements concluded with Grodno Azot OAO, where our sample products were tested and refractory materials were developed, and those with Pigment OAO from Tambov. Together with Pigment OAO, we are working on the creation of the refractory paint. We discussed the development of materials for high-quality ceramic products with representatives of Chepetsky Mechanical Plant AO,” says Alexey Knyazev, deputy dean for Science and Innovation, the Faculty of Chemistry, TSU, director of the Institute of Chemical Technology.

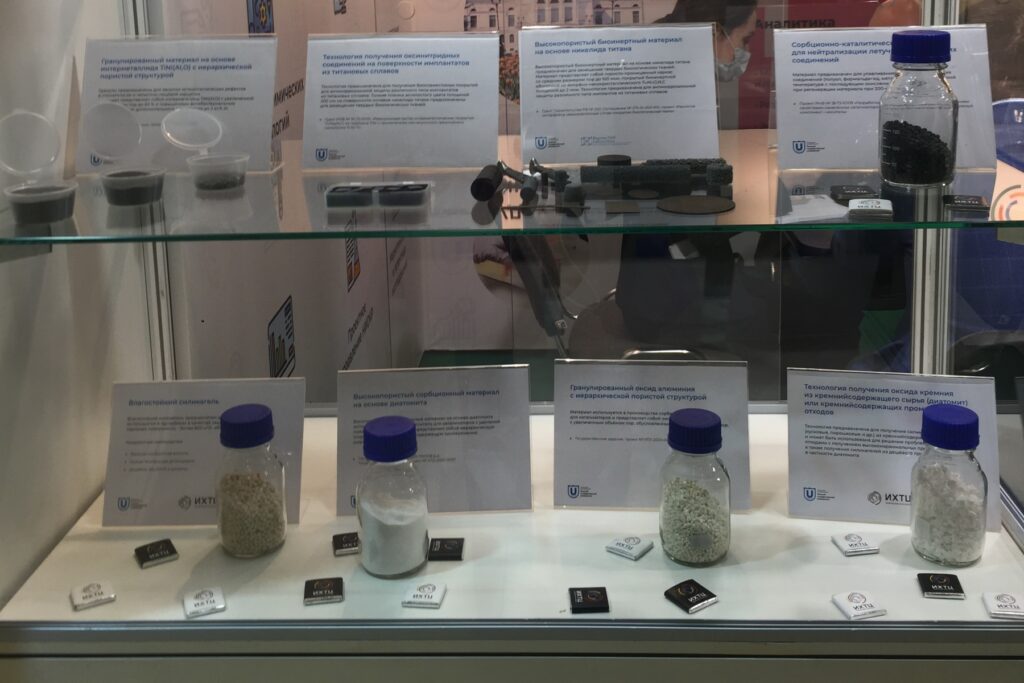

Among the novelties exhibited at the stand of TSU and ICTC, sorption and catalytic materials, including those produced from natural raw materials, as well as irradiation technologies for materials based on titanium alloys, aroused much interest.

The range of sorbents was represented by materials with high sorption capacity, high specific surface area (> 600 m2/g) and low regeneration temperature, which are used, for example, for air drying. Technologies are being developed at Tomsk State University to obtain sorbents, silica gels of various types and related functional products. These technologies employ natural silicon-containing raw materials, for example, diatomite, a material with good sorption and heat-insulating properties. These projects are led by Grigory Mamontov, Senior Researcher at the TSU Laboratory of Catalytic Research.

Grigory Mamontov is also involved in the development of catalysts that are used in the low-temperature capture and subsequent neutralization of volatile organic compounds such as carbon monoxide, toluene, formaldehyde, methanol, and others. For air purification systems, TSU presented a block ozone decomposition catalyst that does not contain precious metals and exhibits a developed cellular structure to provide a high contact area of ozone with the catalytic layer.

Industrial enterprises are interested in catalysts for steam carbon monoxide reforming used in the production of hydrogen for synthesis of ammonia, as well as in catalysts for dehydrogenation of cyclohexanol to cyclohexanone. Oleg Magaev, head of the TSU Laboratory of Catalytic Research, Sergey Galanov and Olga Sidorova, researchers of the Laboratory, and Olga Vodyankina, professor of the Faculty of Chemistry, TSU, are currently working on these projects.

For the first time, the Chemistry exhibition presented medical materials based on titanium alloys and technologies that improve biocompatibility of such materials. In particular, it is a highly porous bioinert material based on titanium nickelide used in replacement of solid biological tissues. The project is led by Aleksey Volynsky, leading researcher of the TSU Laboratory of Superelastic Biointerfaces.

In addition, TSU presented a granular material based on TiNi(Al,O) intermetallic compound with a hierarchical porous structure, designed for filling osteoplastic defects in dentistry and maxillofacial surgery. The technology for obtaining oxynitride biocompatible coatings for anticorrosive protection of various types of titanium alloy implants was presented as well. These projects are being implemented under the leadership of Ekaterina Marchenko, head of the Laboratory for Medical Alloys and Implants with Shape Memory, TSU.

“The presented innovations aroused interest among a number of medical companies. Scientific collaboration is planned with Burnasyan Federal Medical Biophysical Center of Federal Medical Biological Agency to create new coatings with antibacterial properties. Samples of granulated osteoplastic material were transferred to the Sechenov Clinical Center for testing on laboratory animals. A three-day meeting resulted in a number of agreements reached with chemical companies about scientific collaboration,” Marchenko says.

At the joint stand of TSU and ICTC, high-demand products manufactured by Tomsk companies were presented. The Novokhim company manufactures a wide range of fire retarders used in the formulation of fire-retardant materials (paint, varnish, mastic, plastic, etc.). One of the novel products is an odor absorber designed to remove unpleasant odors from wastewater facilities, sludge storage, and industrial sites.

Alexey Knyazev took part in the round table “Development of potential of personnel for the chemical complex”, where training of personnel for industrial partners was discussed. As a result, an agreement was reached with the Sibagro company on targeted training of chemists at the Faculty of Chemistry, TSU, in connection with the construction of the plant for production of polylactide in Sharypovsky district (Krasnoyarsk Territory). In addition, samples of refractory materials developed at ICTC were transferred to RCTU students for study and research.

Source: TSU Press Service.